Overview

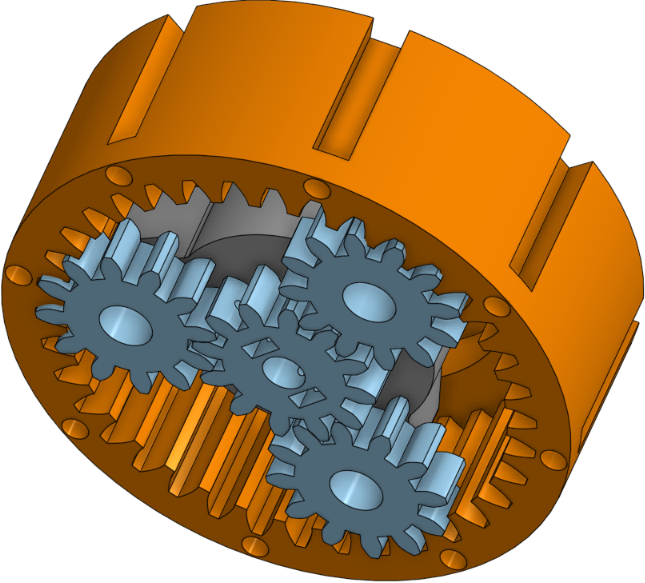

As part of a larger project, this gearbox was designed to be a cost effective solution to greatly increase the torque output of my motors while keeping a small formfactor that a regular gear train could not achieve; with the additional goal of creating something that could be modular and easy to assemble.

Design & Fabrication

With the main goals here being torque output, modularity, and ease of assembly, my design process relied heavily on conducting various virtual builds and sub-assembly fitups

to isolate and improve upon any problematic assembly features in my design.

I wanted something that would use common parts and limited myself toa max of 1 tool change over the entire assembly process;

so careful consideration was made over how I'd select mating features to ensure that I would stick to one mating head size throughout most of the assembly.

the only required tool change was at the beginning of assembly, where I had to insert a grub screw to mate the planetary gear to the motor shaft.

Since every part was to be 3d printed, the geometry of every piece had to be designed with the intent of eliminating any overhangs, as that would negatively

affect print quality.

the modular design intent was achieved by having a mounting feature at the top of the carrier to allow for additional gearboxes to be mounted on top, therefore increasing the torque output

further. If the goal torque is achieved, the option to mount any end effector or gear is also available.

Control & Software

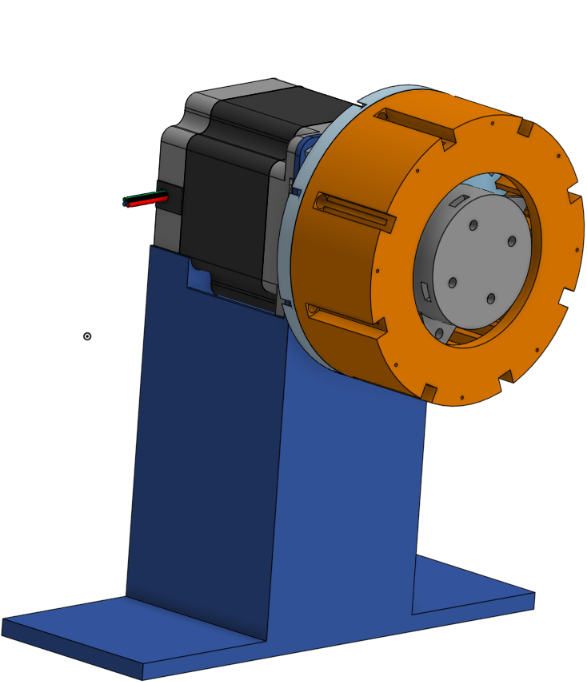

A simple control scheme was used to test motor efficiency. Using a combination of an ESP32 and DM542T motor controller, I would set an increasing voltage through the motor as a function of time. The test script was written in C. An Identical script was then written in arduino to verify that performance would remain the same between boards.

Testing

A test rig was created that was comprised of a digital gauge and a lever arm. The lever arm attatched to the motor would run until it would stall, and the final output force was converted to Newton Meters to find final torque from the gearbox.

Test rig with Nema23 motor attatched

Results

Final force output was about 3.8x the initial input. Accounting for losses from friction and other external factors, this is within my expectations for performance.