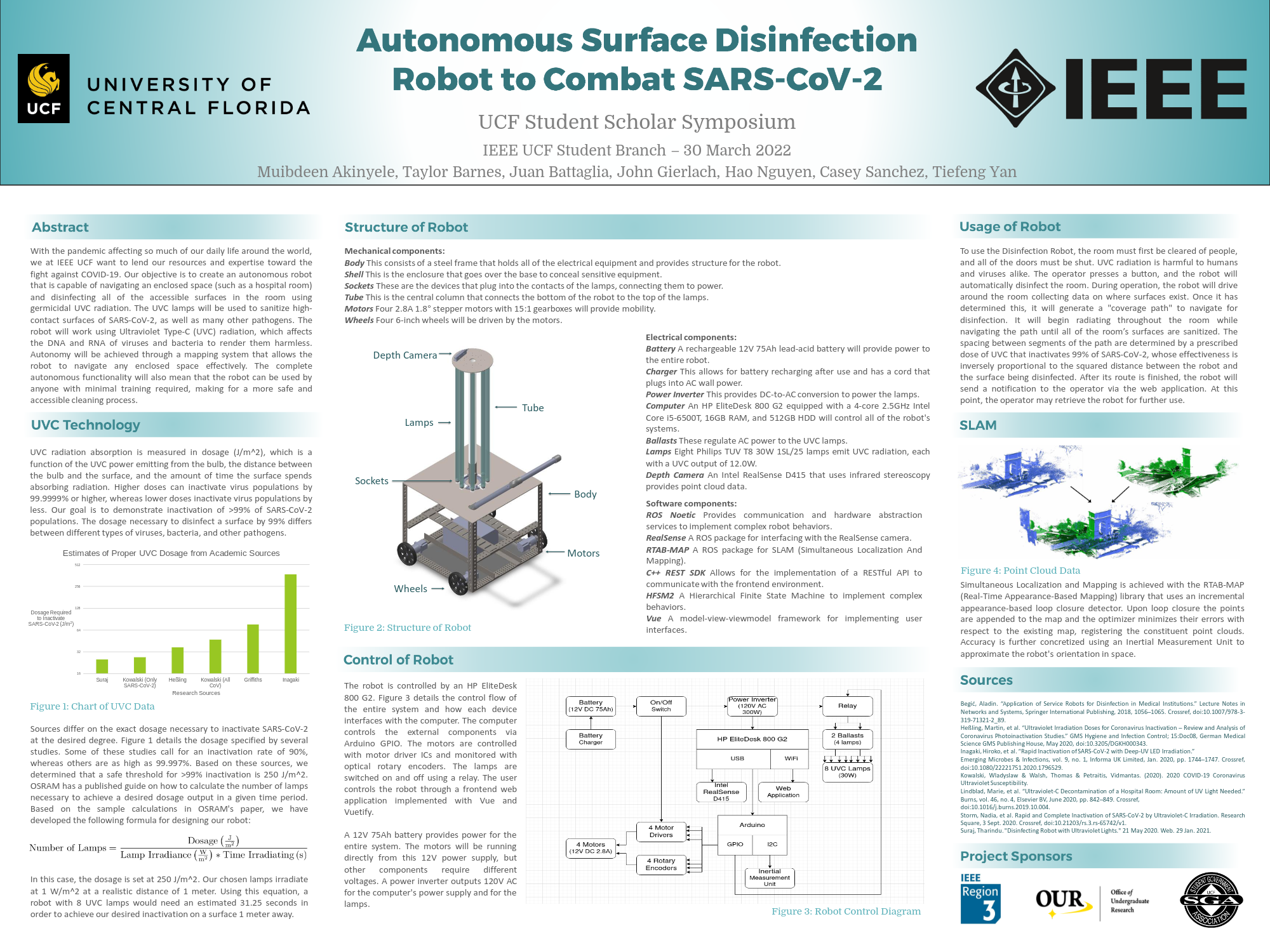

Overview

In order to address the growing concern of mitigating the spread of viruses, I teamed up with IEEE to create an autonomous mobile robot equipped with UVC lamps to patrol around rooms and disinfect surfaces using its UV light. The complete project can be found here.

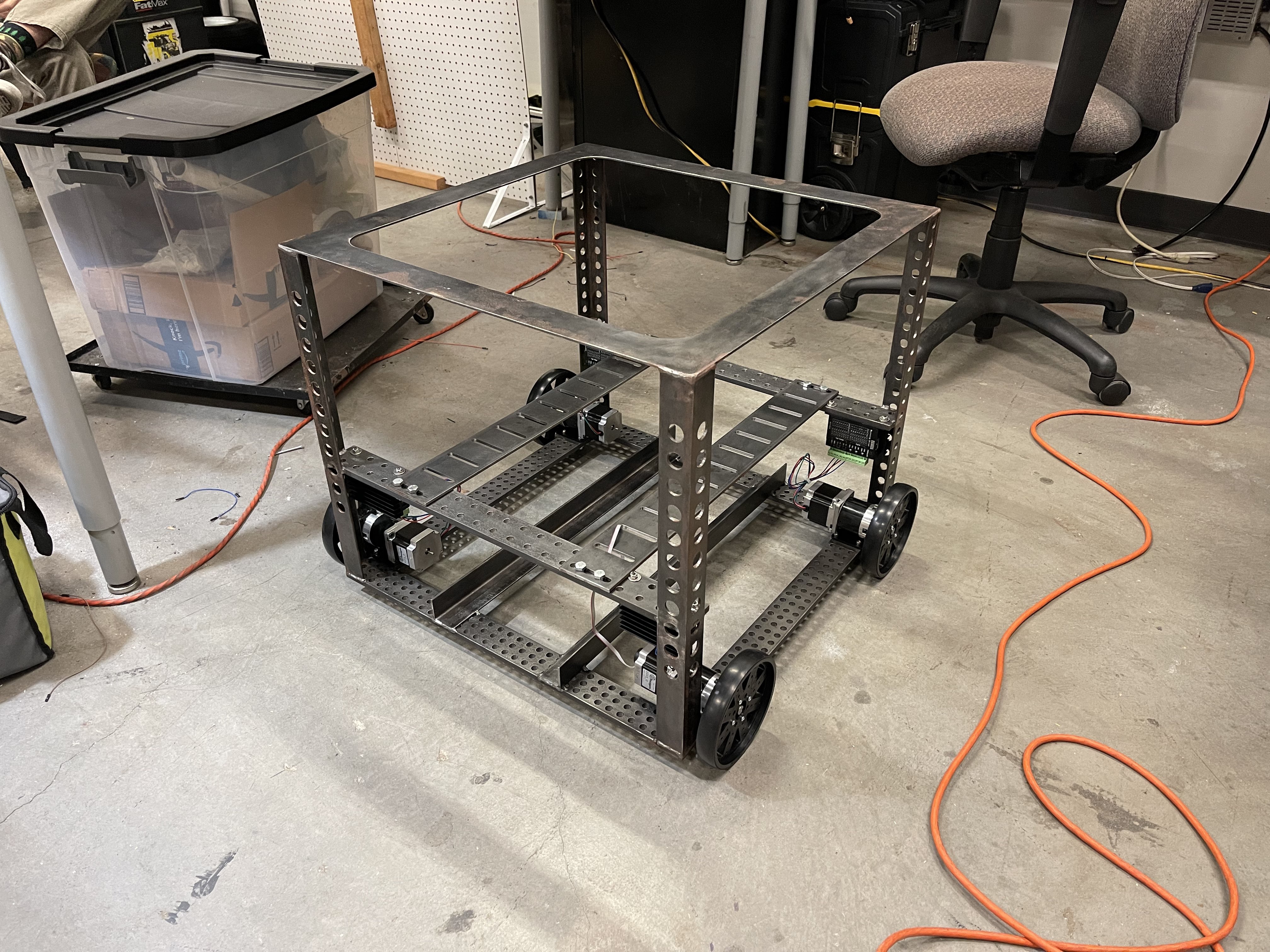

Design & Fabrication

As the Lead mechanical designer for this project, I was tasked with meeting the following design criteria:

1.) UVC light mounting several feet in the air:

The lamp must be above the height of typical desks/tables to properly disinfect surfaces

2.) Differential drive system

Due to limited budget, a simple movement system had to be employed. the differential drive allows us to achieve the bare minumum for patrolling halls and rooms

3.) Camera mounted at highest point of robot

In order for the autonomous stack to best avoid collisions, we opted to have the camera mounted at the highest point of the robot. the camera has a large field of

view so that the autonomous team can get best performance with their software stack.

4.) Power source low to the ground

Keeping the powersource low to the ground allows for easier wiring towards the motor components, and keeps the center of gravity for the assembly low to reduce chances of knockdown via tipping.

Additionally, on top of designing the mechanical components, I also lead the efforts in getting the frame made. I established communication with a local welder and provided the necessary drawing and CAD documents

to aid with getting the job done within our project timelines.

Completed Weld

Completed Weld

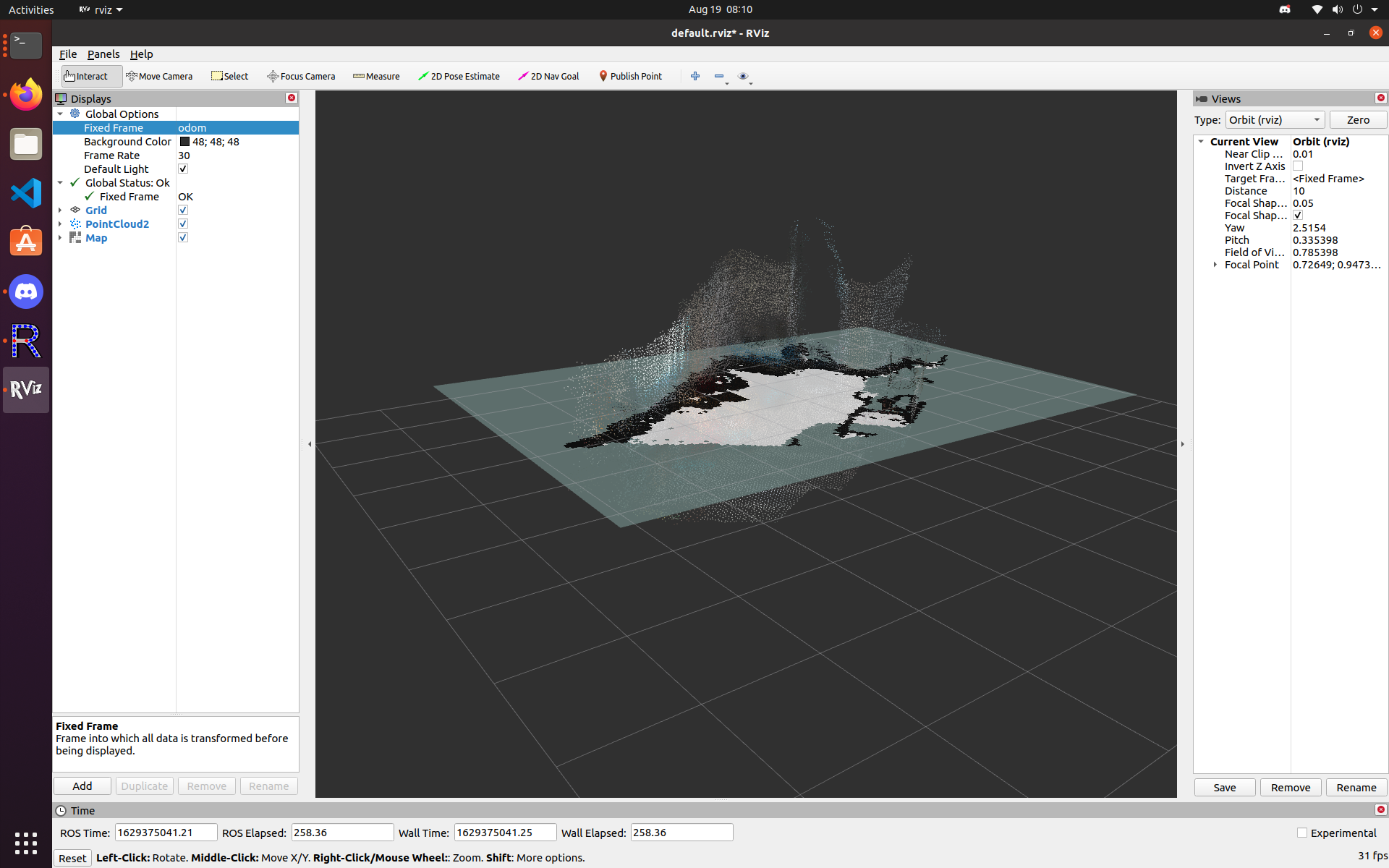

Control & Software

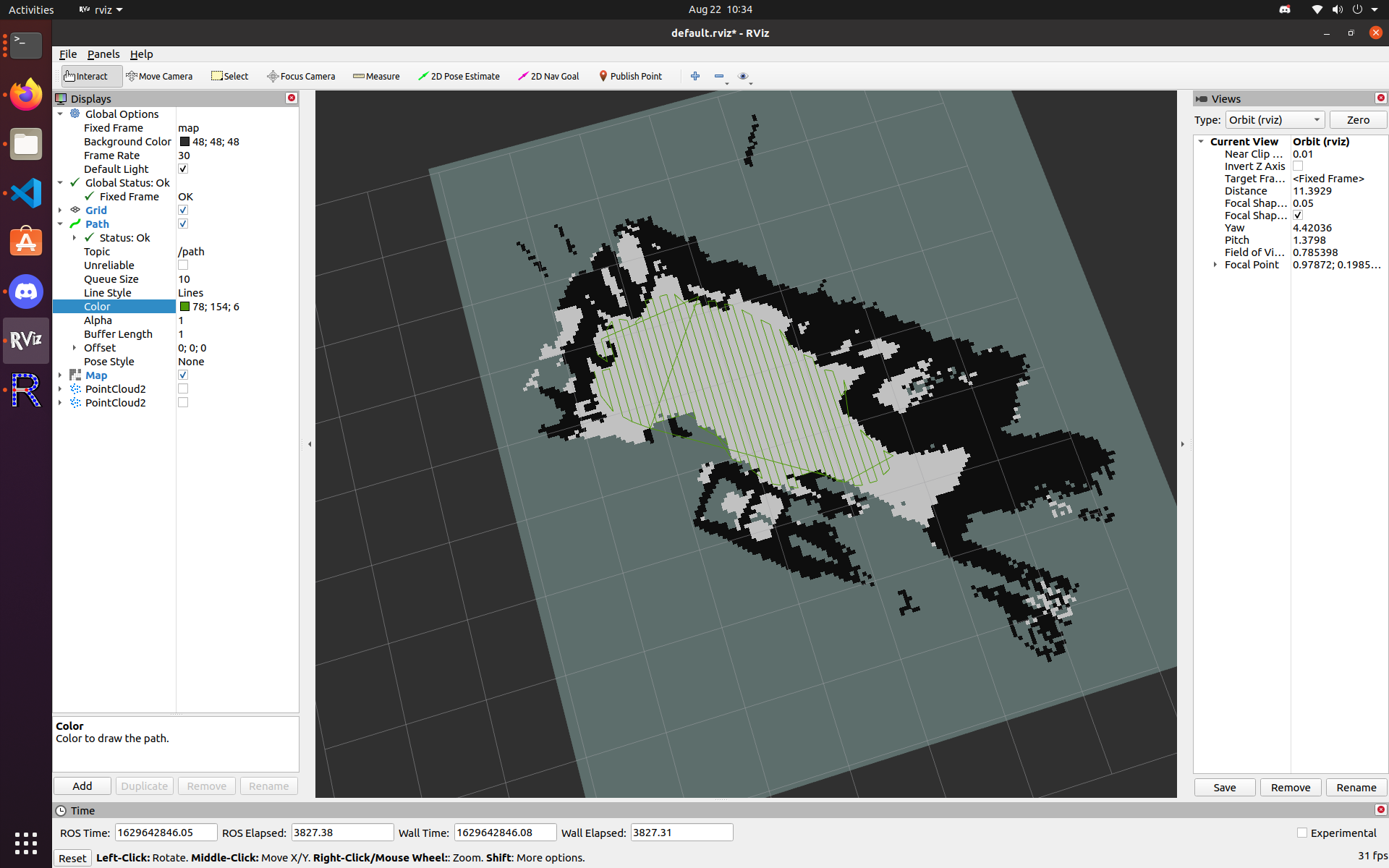

ROS was used as the middleware for this project. we made use of the NAV2 and Rtab-map libraries for navigation and mapping.

Occupancy grid output

Path generation for rooms

Testing

Testing was done by applying the loads of the battery, and motors to the points specified within our CAD file. We measured for any excess signs of stress along the frame.

Results

After welding, we assembled the motors to the frame and passed the rest off to the software team for testing their sub-systems.